Page 518 - Elite Promo Marketing

P. 518

270 271

Printing Techniques Having your products printed with the widest range of

printing techniques has never been so easy. These are

the main techniques to print your logo.

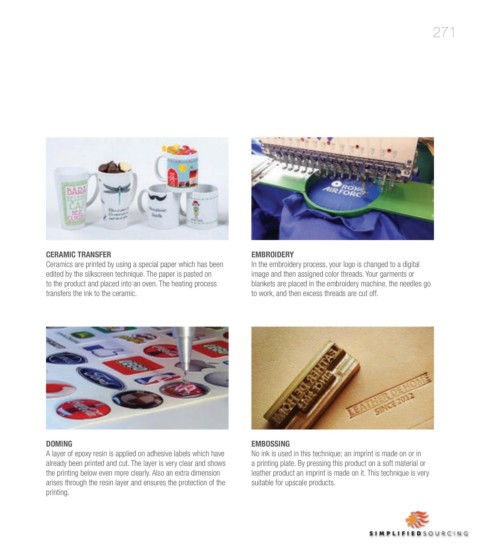

LASER ENGRAVING SCREEN PRINTING (SILKSCREEN) CERAMIC TRANSFER EMBROIDERY

This technique provides a permanent impression which can’t The ink is pushed on the object through gauze which has open Ceramics are printed by using a special paper which has been In the embroidery process, your logo is changed to a digital

be modified. Metal products are the most appropriate for this and closed parts. The print is pressed on by a scraper which edited by the silkscreen technique. The paper is pasted on image and then assigned color threads. Your garments or

technique. The upper layer of the material is removed with is moved across the gauze. Screen printing is used to print flat to the product and placed into an oven. The heating process blankets are placed in the embroidery machine, the needles go

a laser. Colors can’t be applied with this technique and are products. For products with a certain rounding such as buckets, transfers the ink to the ceramic. to work, and then excess threads are cut off.

determined by the material and/or other colored under layers of the round silkscreen printing technique is used. With this

the products. technique almost every product can be printed.

PAD PRINTING (TAMPON PRINTING) HEAT TRANSFER PRINTING DOMING EMBOSSING

A negative film is made and placed on a cliché. The cliché In this technique your imprint is applied on a (transfer) paper. A layer of epoxy resin is applied on adhesive labels which have No ink is used in this technique; an imprint is made on or in

plate is exposed to light with the film. The exposed part of the The product is pressed together with the transfer paper at high already been printed and cut. The layer is very clear and shows a printing plate. By pressing this product on a soft material or

plate is hardened. The unexposed part gets a small impression. temperature. The transfer paper attaches itself to the product the printing below even more clearly. Also an extra dimension leather product an imprint is made on it. This technique is very

The plate is put into the machine and filled with ink, the through the pressure and heat. This technique is very suitable arises through the resin layer and ensures the protection of the suitable for upscale products.

scraper slides over the plate which leads to a small layer of ink for flexible materials like umbrellas. printing.

remaining in the impression. This is taken up by the silicone

stamp and placed on the object, such as a pen.