Page 50 - Elite Promotional Marketing

P. 50

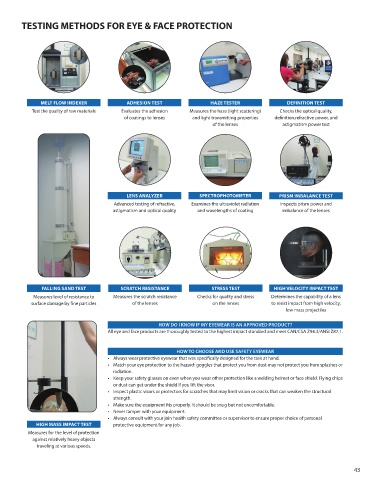

TESTING METHODS FOR EYE & FACE PROTECTION

MELT FLOW INDEXER ADHESION TEST HAZE TESTER DEFINITION TEST

Test the quality of raw materials Evaluates the adhesion Measures the haze (light scattering) Checks the optical quality,

of coatings to lenses and light transmitting properties definition,refractive power, and

of the lenses astigmatism power test

LENS ANALYZER SPECTROPHOTOMETER PRISM IMBALANCE TEST

Advanced testing of refractive, Examines the ultraviolet radiation Inspects prism power and

astigmatism and optical quality and wavelengths of coating imbalance of the lenses

FALLING SAND TEST SCRATCH RESISTANCE STRESS TEST HIGH VELOCITY IMPACT TEST

Measures level of resistance to Measures the scratch resistance Checks for quality and stress Determines the capability of a lens

surface damage by fine particles of the lenses on the lenses to resist impact from high velocity,

low mass projectiles

HOW DO I KNOW IF MY EYEWEAR IS AN APPROVED PRODUCT?

All eye and face products are thoroughly tested to the highest impact standard and meet CAN/CSA Z94.3/ANSI Z87.1.

HOW TO CHOOSE AND USE SAFETY EYEWEAR

• Always wear protective eyewear that was specifically designed for the task at hand.

• Match your eye protection to the hazard: goggles that protect you from dust may not protect you from splashes or

radiation.

• Keep your safety glasses on even when you wear other protection like a welding helmet or face shield. Flying chips

or dust can get under the shield if you lift the visor.

• Inspect plastic visors or protectors for scratches that may limit vision or cracks that can weaken the structural

strength.

• Make sure the equipment fits properly. It should be snug but not uncomfortable.

• Never tamper with your equipment.

• Always consult with your join health safety committee or supervisor to ensure proper choice of personal

HIGH MASS IMPACT TEST protective equipment for any job.

Measures for the level of protection

against relatively heavy objects

traveling at various speeds.

43