Page 21 - Elite Promo Marketing

P. 21

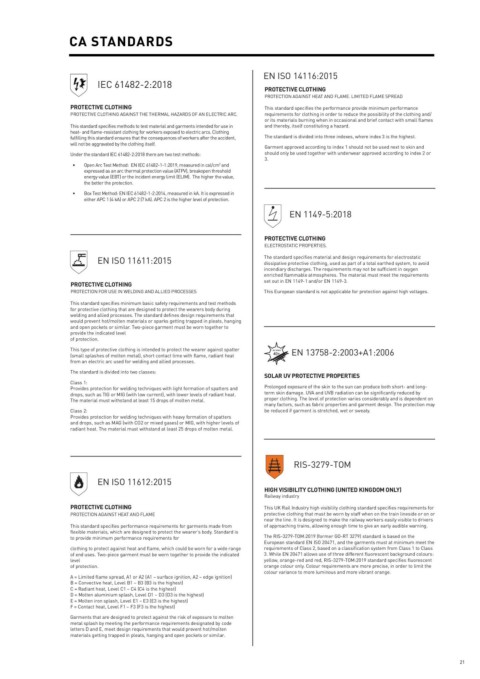

CA STANDARDS

EN ISO 14116:2015

IEC 61482-2:2018 PROTECTIVE CLOTHING

PROTECTION AGAINST HEAT AND FLAME. LIMITED FLAME SPREAD

PROTECTIVE CLOTHING This standard specifies the performance provide minimum performance

PROTECTIVE CLOTHING AGAINST THE THERMAL HAZARDS OF AN ELECTRIC ARC. requirements for clothing in order to reduce the possibility of the clothing and/

or its materials burning when in occasional and brief contact with small flames

This standard specifies methods to test material and garments intended for use in and thereby, itself constituting a hazard.

heat- and flame-resistant clothing for workers exposed to electric arcs. Clothing

fulfilling this standard ensures that the consequences of workers after the accident, The standard is divided into three indexes, where index 3 is the highest.

will not be aggravated by the clothing itself.

Garment approved according to index 1 should not be used next to skin and

Under the standard IEC 61482-2:2018 there are two test methods: should only be used together with underwear approved according to index 2 or

3.

• Open Arc Test Method: EN IEC 61482-1-1:2019, measured in cal/cm 2 and

expressed as an arc thermal protection value (ATPV), breakopen threshold

energy value (EBT) or the incident energy limit (ELIM). The higher the value,

the better the protection.

• Box Test Method: EN IEC 61482-1-2:2014, measured in kA. It is expressed in

either APC 1 (4 kA) or APC 2 (7 kA). APC 2 is the higher level of protection.

EN 1149-5:2018

PROTECTIVE CLOTHING

ELECTROSTATIC PROPERTIES.

EN ISO 11611:2015 The standard specifies material and design requirements for electrostatic

dissipative protective clothing, used as part of a total earthed system, to avoid

incendiary discharges. The requirements may not be sufficient in oxygen

enriched flammable atmospheres. The material must meet the requirements

PROTECTIVE CLOTHING set out in EN 1149-1 and/or EN 1149-3.

PROTECTION FOR USE IN WELDING AND ALLIED PROCESSES This European standard is not applicable for protection against high voltages.

This standard specifies minimum basic safety requirements and test methods

for protective clothing that are designed to protect the wearers body during

welding and allied processes. The standard defines design requirements that

would prevent hot/molten materials or sparks getting trapped in pleats, hanging

and open pockets or similar. Two-piece garment must be worn together to

provide the indicated level

of protection.

This type of protective clothing is intended to protect the wearer against spatter EN 13758-2:2003+A1:2006

(small splashes of molten metal), short contact time with flame, radiant heat

from an electric arc used for welding and allied processes.

The standard is divided into two classes:

SOLAR UV PROTECTIVE PROPERTIES

Class 1:

Provides protection for welding techniques with light formation of spatters and Prolonged exposure of the skin to the sun can produce both short- and long-

drops, such as TIG or MIG (with low current), with lower levels of radiant heat. term skin damage. UVA and UVB radiation can be significantly reduced by

The material must withstand at least 15 drops of molten metal. proper clothing. The level of protection varies considerably and is dependent on

many factors, such as fabric properties and garment design. The protection may

Class 2: be reduced if garment is stretched, wet or sweaty.

Provides protection for welding techniques with heavy formation of spatters

and drops, such as MAG (with CO2 or mixed gases) or MIG, with higher levels of

radiant heat. The material must withstand at least 25 drops of molten metal.

RIS-3279-TOM

EN ISO 11612:2015

HIGH VISIBILITY CLOTHING (UNITED KINGDOM ONLY)

Railway industry

PROTECTIVE CLOTHING This UK Rail Industry high visibility clothing standard specifies requirements for

PROTECTION AGAINST HEAT AND FLAME protective clothing that must be worn by staff when on the train lineside or on or

near the line. It is designed to make the railway workers easily visible to drivers

This standard specifies performance requirements for garments made from of approaching trains, allowing enough time to give an early audible warning.

flexible materials, which are designed to protect the wearer’s body. Standard is

to provide minimum performance requirements for The RIS-3279-TOM:2019 (former GO-RT 3279) standard is based on the

European standard EN ISO 20471, and the garments must at minimum meet the

clothing to protect against heat and flame, which could be worn for a wide range requirements of Class 2, based on a classification system from Class 1 to Class

of end uses. Two-piece garment must be worn together to provide the indicated 3. While EN 20471 allows use of three different fluorescent background colours:

level yellow, orange-red and red, RIS-3279-TOM:2019 standard specifies fluorescent

of protection. orange colour only. Colour requirements are more precise, in order to limit the

colour variance to more luminous and more vibrant orange.

A = Limited flame spread, A1 or A2 (A1 – surface ignition, A2 – edge ignition)

B = Convective heat, Level B1 – B3 (B3 is the highest)

C = Radiant heat, Level C1 – C4 (C4 is the highest)

D = Molten aluminium splash, Level D1 – D3 (D3 is the highest)

E = Molten iron splash, Level E1 – E3 (E3 is the highest)

F = Contact heat, Level F1 – F3 (F3 is the highest)

Garments that are designed to protect against the risk of exposure to molten

metal splash by meeting the performance requirements designated by code

letters D and E, meet design requirements that would prevent hot/molten

materials getting trapped in pleats, hanging and open pockets or similar.

21